精密管高端定制

更新时间:2025-10-02 17:53:57 ip归属地:宜春,天气:多云,温度:24-34 浏览:3次

- 发布企业

- 大鼎金属材料(宜春市高安区分公司)

- 报价

- 电议

- 品牌

- 电议

- 供货总量

- 电议

- 运费

- 电议

- 关键词

- 无缝钢管

- 所在地

- 高新区新东环路路西钢材市场58号

- 联系电话

- 0635-8888940

- 手机

- 15315719115

- 联系人

- 孙经理 请说明来自商助贸易宝,优惠更多

详细介绍

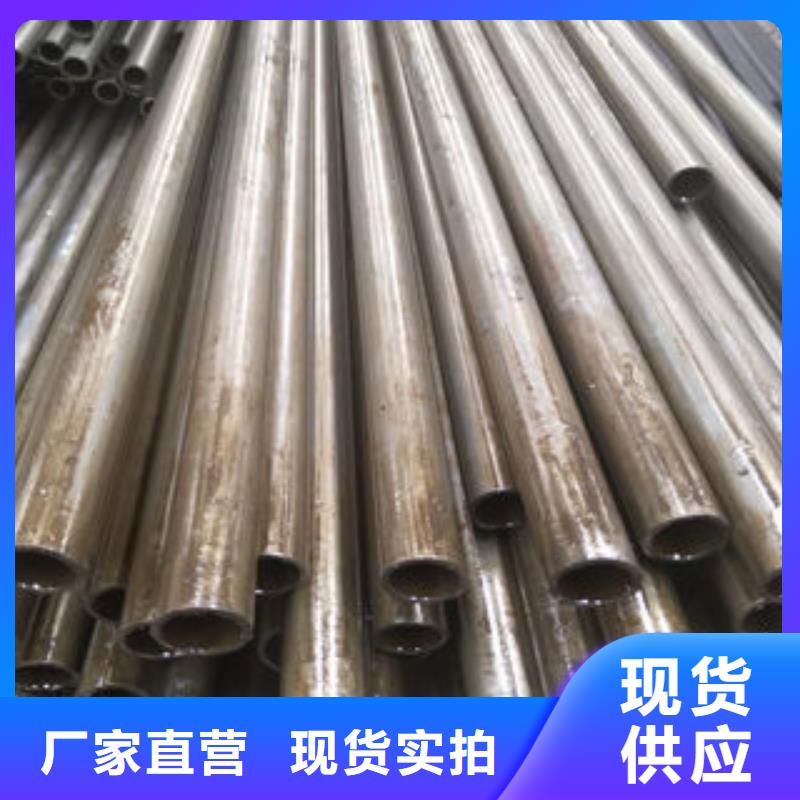

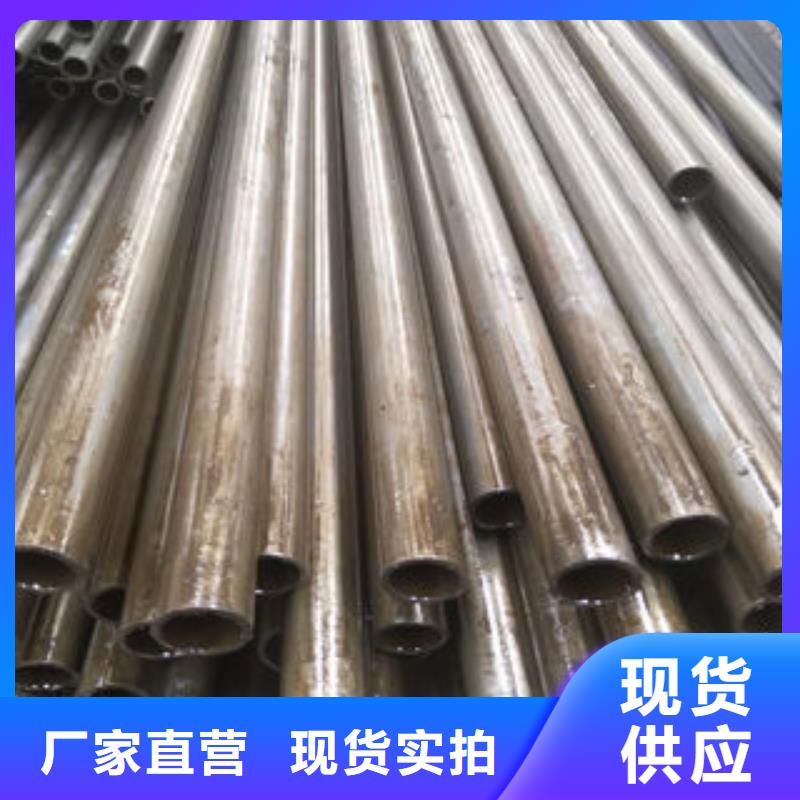

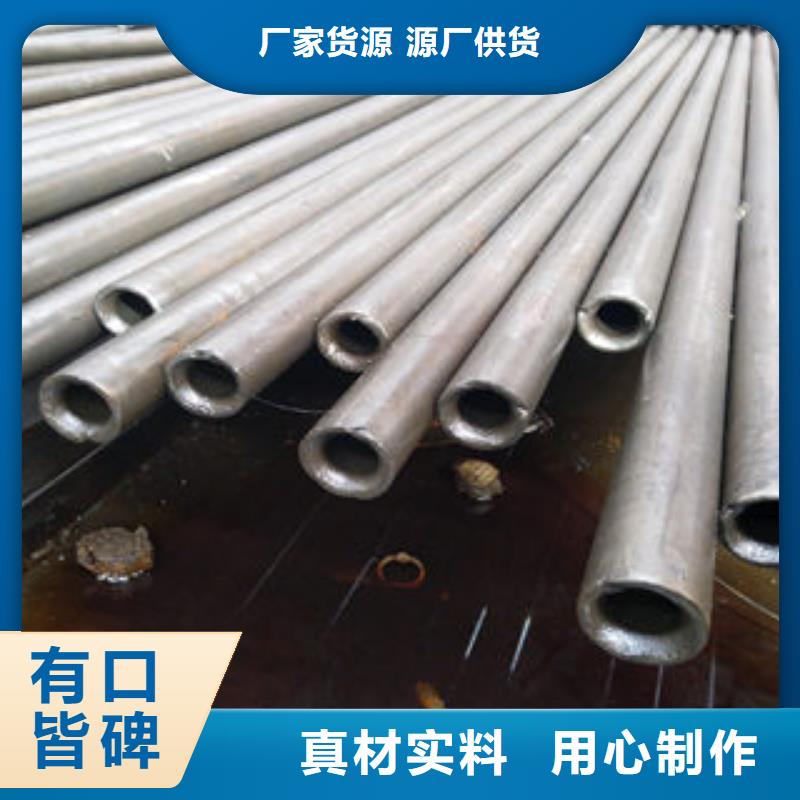

宜春高安大鼎金属材料有限公司技术力量雄厚,设备先进, 无缝钢管生产工艺规范,检测手段齐全,各项管理严格,加之多品种、系列化的配套服务,重质量、守信誉的经营战略,给企业带来了勃勃生机,成为宜春高安创税大户。 企业衷心感谢各界朋友对我方 无缝钢管产品的信任与支持,在今后的交往中,我们将一如既往,以“优异的 无缝钢管产品、良好的信誉、贴心的服务”奉献给用户,造福社会。

Oil quenching causes surface deterioration easily. Due to the high surface activity, significant thin layer carburization can occur under the action of short and high temperature oil film. In addition, the adhesion of carbon black and oil on the surface is not conducive to simplifying the heat treatment process. The development of vacuum quenching technology mainly lies in the development of single gas cooled quenching furnace with excellent performance. Double chamber furnace can also be used for gas quenching (front chamber air jet cooling), but the operation of the two stations makes it difficult to load a large number of furnace, and easy to cause workpiece deformation or change the direction of workpiece quenching. NG deformation during high temperature movement.

山东大鼎钢管厂公式计算钢管的理论重量:W=(D-S)*S*0.02466,其中W=钢管每米的重量;S=钢管的公称壁厚;D=钢管的公称外径,光亮管的表面质量i清洁、无氧化层、无裂纹、折叠、轧制、结疤、分离层和条纹。

山东大鼎金属材料有限公司Precision seamless steel pipe (cold-drawn and cold-rolled) has high precision, no oxidation coating inside and outside the pipe, smooth and smooth surface, uniform wall thickness, high precision, small diameter of thin-walled tube to ensure that the error of the outside diameter of the tube in the inner and outer surface of the pipe presents varying degrees and quantities of corrugated ring marks, some are continuous, some are intermittent, may be the entire circle, there are. Not the whole circle. poor quality of pickling and lubrication, increase and change of friction during drawing, mechanical properties of steel pipe in length direction after heat treatment are not consistent, mandrel length and fineness are too large, and the position of mandrel before.

山东大鼎钢管厂拥有台大中型冷拔机、两台辊底热处理炉、台大中型穿孔机和台热轧钢管机组三套先进的生产设备和成熟的生产工艺。公司拥有现代化的科研中心,拥有强大的性能测试、工艺性能测试、涡流测试、超声波测试、水力测试、金相测试、高精度碳硫分析等一整套测试方法,并拥有一批高素质的技术人员和检查员。硬度试验是根据规定的条件将硬质压头缓慢压入试样表面,然后测试压痕深度或尺寸,从而确定材料的硬度。